Honda files for patent involving 2-stroke and fuel injection

(Click link above to open in new window)

This has some interesting implications in so much as it certainly demonstrates that there's continued interest and research involving 2-strokes. Indeed for power to weight/displacement, they're incredibly efficient engines.

Though this particular motor in the patent looks distinctly low performance - such as might be used for a generator or pump, we can always hope that the technology will be used further to help clean up 2-stroke emissions so that we might see them more frequently again both on and off the race track.

More to follow....

2-stroke-racing

Sunday 24 January 2016

Friday 28 August 2015

Mini Moto / Pocket Bike Exhaust Port Mods - Part 2

This post is a follow up to an earlier one which detailed some of the issues with port shape mismatch between mini moto / pocket bike cylinder heads and racing exhaust pipes.

The earler post is here: Mini Moto / Pocket Bike Exhaust Port Mods .

Port matching, which consists of reshaping port outlets to be size and shape matched for better flow, is all but standard practice in all forms of motorsport and is often done at home by enthusiasts who are looking to extract all the performance possible from their engines.

Mini motos / pocket bikes are almost always tuned to varying degrees and indeed, the internet is full of articles and websites dedicated towards helping you make your moto faster. There are many articles which point towards 'opening up' the exhaust port on these bikes, but for all the time and effort being put into opening them up, there's almost always a huge port mismatch between the cylinder head and the exhaust pipe.

As I showed in the initial post, this is the typical 'view' the exhaust has as it exits the cylinder head towards the exhaust pipe:

There's much more detail, along with a couple of crude flow models in the initial post, however as I'd touched upon when writing that, it's not only the area in red here, representing the inlet to the racing exhaust which is the problem, it's the turbulence caused by the exhaust being deflected around this mismatch that has a much greater impact than what is illustrated. Obviously any more 'opening up' of the exhaust port on the head is going to exacerbate this effect instead of serving to resolve it, meaning that another solution was due.

I've also touched upon in the initial post the options of welding the port up and re-machining it to a shape which would match up better to the pipe, or even of possibly using JBWeld as has been suggested. (Note: do NOT use JBWeld to rehape your exhaust port - it will quickly break down under those conditions and you'll have much larger problems than just port mismatch)

The ideal to all of the above would be something which could be bolted on in just a few minutes, requiring an absolute minimum of prep to either of the mating surfaces and ideally requiring no welding or machining whilst offering great flow improvements.

Following on now to the CAD and flow models of the original post, here are some images of a test-fit piece which I've machined from wood. There's a slightly more revised version I've now prototyped in bronze and have working in practice /being tested, but I'd prefer to keep that version under wraps until its' for sale. To the naked eye, there's not much difference at all between that one and this, but there are subtle refinements which manage to extract another couple of CFM of flow.

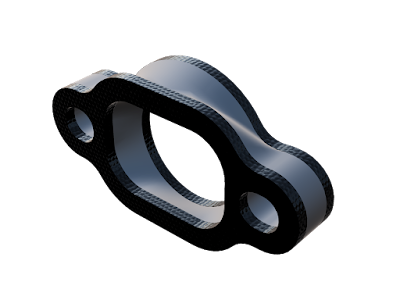

Finally, after that lengthly introduction, here's the wood model of the 'FlangeFlow' port adapter.

I've done a few of these from hardwood as they were quite quick to knock out on the CNC and yet were rigid enough to survive being mocked up and flow tested on several head/pipe combinations.

Unfortunately the available equipment for the flow testing was less than ideal and was rather 'mad scientist / high school science fair' in appearance, but the purpose was served and we were able to reaffirm that the slight changes we were making were in the right direction. We do have formal flow-testing scheduled for the near future.

How much of a difference do the FlangeFlow adapters make? In simulations, >15% was common to see, in the real world, we'll be backing all this up with some extended dyno testing in the near future, but I can tell you this for the moment: You can hear the difference, certainly feel the difference in acceleration/top speed, and it required stepping up one jet size on one 'stage 2' motor, and two jet sizes on a 'stage 3' motor to maintain the air/fuel ratio. Both the motors tested were 49cc air cooled (the initial target platform for these adapters), and both had been initially built with off-the-shelf available components which were then race prepped and the rotating assembly carefully balanced.

The 3x test riders (two very accomplished racers and one amateur) all indicated they felt a 'big improvement' in midrange and especially top end. Acceleration out of corners was improved and straightline speed increased so that one rider commented on having to 'hit the brakes a little earlier to scrub off more speed' before the corner.

These are a couple of images showing the FlowFlange situated against a couple of different cylinder heads and against 2x different race pipes. Note that all the misalignment is addressed and that although kept to under 6mm thick so as not to cause exhaust fitment issues, the flow transition from one shape to the other is radically improved.

On these two heads (by different manufacturers with different markings, having had only the ports smoothed but not hogged out, you can clearly see how linearly the FlangeFlow mates to the port shape for a seamless, uninterrupted exhaust flow.

Also, in the reverse direction, with the exhaust pulse pushing the extra air/fuel back from the pipe into the head to be burned, there's a much improved flowpath. This contributes to better cylinder filling, higher cylinder pressures, and more power all the way through the RPM range.

Again, the clear, uninterrupted flow path can clearly be seen as it's presented to the exhaust flow from the head into the pipe.

The FlangeFlow will soon be available as part of an easy, 5 minute bolt-on kit which in most circumstances will aid in exhaust port flow by a minimum of 15%, in many cases, much higher. The kit will come with new, spring loaded mounting hardware, custom gaskets - one for each side of the FlowFlange, the bronze FlowFlange itself, stickers, and an instruction sheet.

The earler post is here: Mini Moto / Pocket Bike Exhaust Port Mods .

Port matching, which consists of reshaping port outlets to be size and shape matched for better flow, is all but standard practice in all forms of motorsport and is often done at home by enthusiasts who are looking to extract all the performance possible from their engines.

Mini motos / pocket bikes are almost always tuned to varying degrees and indeed, the internet is full of articles and websites dedicated towards helping you make your moto faster. There are many articles which point towards 'opening up' the exhaust port on these bikes, but for all the time and effort being put into opening them up, there's almost always a huge port mismatch between the cylinder head and the exhaust pipe.

As I showed in the initial post, this is the typical 'view' the exhaust has as it exits the cylinder head towards the exhaust pipe:

|

| Head To Pipe Exhaust Port Mismatch |

There's much more detail, along with a couple of crude flow models in the initial post, however as I'd touched upon when writing that, it's not only the area in red here, representing the inlet to the racing exhaust which is the problem, it's the turbulence caused by the exhaust being deflected around this mismatch that has a much greater impact than what is illustrated. Obviously any more 'opening up' of the exhaust port on the head is going to exacerbate this effect instead of serving to resolve it, meaning that another solution was due.

I've also touched upon in the initial post the options of welding the port up and re-machining it to a shape which would match up better to the pipe, or even of possibly using JBWeld as has been suggested. (Note: do NOT use JBWeld to rehape your exhaust port - it will quickly break down under those conditions and you'll have much larger problems than just port mismatch)

The ideal to all of the above would be something which could be bolted on in just a few minutes, requiring an absolute minimum of prep to either of the mating surfaces and ideally requiring no welding or machining whilst offering great flow improvements.

Following on now to the CAD and flow models of the original post, here are some images of a test-fit piece which I've machined from wood. There's a slightly more revised version I've now prototyped in bronze and have working in practice /being tested, but I'd prefer to keep that version under wraps until its' for sale. To the naked eye, there's not much difference at all between that one and this, but there are subtle refinements which manage to extract another couple of CFM of flow.

Finally, after that lengthly introduction, here's the wood model of the 'FlangeFlow' port adapter.

|

| Wood Prototype FlangeFlow Port Adapter |

I've done a few of these from hardwood as they were quite quick to knock out on the CNC and yet were rigid enough to survive being mocked up and flow tested on several head/pipe combinations.

Unfortunately the available equipment for the flow testing was less than ideal and was rather 'mad scientist / high school science fair' in appearance, but the purpose was served and we were able to reaffirm that the slight changes we were making were in the right direction. We do have formal flow-testing scheduled for the near future.

How much of a difference do the FlangeFlow adapters make? In simulations, >15% was common to see, in the real world, we'll be backing all this up with some extended dyno testing in the near future, but I can tell you this for the moment: You can hear the difference, certainly feel the difference in acceleration/top speed, and it required stepping up one jet size on one 'stage 2' motor, and two jet sizes on a 'stage 3' motor to maintain the air/fuel ratio. Both the motors tested were 49cc air cooled (the initial target platform for these adapters), and both had been initially built with off-the-shelf available components which were then race prepped and the rotating assembly carefully balanced.

The 3x test riders (two very accomplished racers and one amateur) all indicated they felt a 'big improvement' in midrange and especially top end. Acceleration out of corners was improved and straightline speed increased so that one rider commented on having to 'hit the brakes a little earlier to scrub off more speed' before the corner.

These are a couple of images showing the FlowFlange situated against a couple of different cylinder heads and against 2x different race pipes. Note that all the misalignment is addressed and that although kept to under 6mm thick so as not to cause exhaust fitment issues, the flow transition from one shape to the other is radically improved.

|

| FlangeFlow / Port View 1 |

On these two heads (by different manufacturers with different markings, having had only the ports smoothed but not hogged out, you can clearly see how linearly the FlangeFlow mates to the port shape for a seamless, uninterrupted exhaust flow.

Also, in the reverse direction, with the exhaust pulse pushing the extra air/fuel back from the pipe into the head to be burned, there's a much improved flowpath. This contributes to better cylinder filling, higher cylinder pressures, and more power all the way through the RPM range.

|

| FlangeFlow / Port View 2 |

Additionally, these pictures show the FlowFlange positioned against a typical race pipe. As indicated in the previous post, of the several exhaust I had access to, all had an inlet diameter within 1mm or so of each other. I've matched the exhaust side up to the proper racing pipes but matching to more mainstream aftermarket pipes is also excellent.

|

| Exhaust Pipe Match View 1 |

Again, the clear, uninterrupted flow path can clearly be seen as it's presented to the exhaust flow from the head into the pipe.

|

| Exhaust Pipe Match View 2 |

Though not specifically related to the workings or benefits of the FlowFlange itself,

Below are several images of the FlowFlange wood model as it was being cut on the CNC machine.

|

| Beginning of first top side CNC cut |

|

| 1/3 of of the first top side cut done |

|

| Approaching full depth now |

|

| External profile CNC machinig |

|

| CNC shaping the internal port contour |

|

| A bit more port clean up |

|

| Perimeter milling |

|

| Milling away the fixture supports |

The FlowFlange is 100% designed, manufactured, and packaged in the UK.

enquiries can be sent to me or to info@mgdesignlondon.com

Labels:

2 stroke,

39cc,

49cc,

air cooled,

CAG,

Cylinder Head,

Exhaust,

High Performance,

mini moto,

Pipe,

pocket bike,

Port,

Porting,

Racing,

tuning,

water cooled

Wednesday 26 August 2015

New Mini Moto / Pocket Bike Cylinder Barrel / Head Design for Maximum Performance

This post is going to be a sneak preview of a new cylinder head design I'm working on for 39/49cc aircooled engines typically used in Pocket Bikes.

An initial design parameter of this design is full backwards compatibility with existing engine cases and engine internals, as such, I've stayed with a fairly conventional appearing external shape.

Ultimately these heads will be available paired with the billet engine cases which are in the works, but for the near future, the barrels and a custom cylinder head with a selection of compression dome inserts will be available.

The following images are WIP CAD models. There's revisions being done and lots of flow modelling at various piston positions (every 10 degrees of crank rotation.).

You can see from these images that the cooling fins haven't been modeled yet. They're going to be positioned and their density determined by thermodynamic modelling in an effort to gain some level of control over the conditions in the combustion chamber.

Of note is the round exhaust port which has been shaped and sized to match up seamlessly to the best race pipes for these heads. This alone makes a significant difference in the amount of flow the heads will sustain.

The interior or the exhaust port has been carefully shaped, and although the bottom 10% or so isn't really visible in this view because of the port floor contour, the overall shape can be seen.

The ceiling of the port has been raised 2.25 mm from stock on the 39CC variant, and 2.85 mm from stock on the 49CC version when compared to standard 'High Performance Heads'. Also, much work has been done refining the shape of the port transition and ensuring that flow is optimised from the very moment the port is opened, through the piston being all the way to BDC.

Thought has been given too towards the air/fuel charge being pulse returned from the exhaust pipe with the floor of the port being shaped to direct this flow precisely where it's most desirable for the custom shape of the combustion chamber.

Lastly, using very carefully shaped and flow tuned contours for all the ports has yielded great results. The ports all have semi-angular domed 'ceilings' with multiple internal angles which direct the incoming air/fuel charge precisely yielding a very desirable swirl which works in careful conjunction with the small returning air/fuel charge from the pipe.

When I have achieved precisely what I intend to with this modelling, I shall post some video of the flow modelling during the compression phase of the engine operation but suffice to say for now that this barrel / head combo is going to make more power, more reliably, and allow for a wider range of tuning options whilst offering a complete intake charge burn than anything else on the market available for the air-cooled engines.

Lastly, provision has been made during the design of these heads for a 6mm thick thermal insulating layer between the base of the barrel and the engine cases. This should serve to not only allow the bearings to run cooler and longer, but to keep the air/fuel charge cooler and denser as it enters the combustion chamber for further improved power.

These heads will NOT need to be ported, smoothed or modded in any way to offer outstanding performance. In all actuality, these heads are tuned to the point that any modifications will likely be detrimental to performance.

More info to follow shortly.

An initial design parameter of this design is full backwards compatibility with existing engine cases and engine internals, as such, I've stayed with a fairly conventional appearing external shape.

Ultimately these heads will be available paired with the billet engine cases which are in the works, but for the near future, the barrels and a custom cylinder head with a selection of compression dome inserts will be available.

The following images are WIP CAD models. There's revisions being done and lots of flow modelling at various piston positions (every 10 degrees of crank rotation.).

|

| Cylinder Barrel Without Fins |

You can see from these images that the cooling fins haven't been modeled yet. They're going to be positioned and their density determined by thermodynamic modelling in an effort to gain some level of control over the conditions in the combustion chamber.

Of note is the round exhaust port which has been shaped and sized to match up seamlessly to the best race pipes for these heads. This alone makes a significant difference in the amount of flow the heads will sustain.

|

| Exhaust Port View |

The interior or the exhaust port has been carefully shaped, and although the bottom 10% or so isn't really visible in this view because of the port floor contour, the overall shape can be seen.

The ceiling of the port has been raised 2.25 mm from stock on the 39CC variant, and 2.85 mm from stock on the 49CC version when compared to standard 'High Performance Heads'. Also, much work has been done refining the shape of the port transition and ensuring that flow is optimised from the very moment the port is opened, through the piston being all the way to BDC.

Thought has been given too towards the air/fuel charge being pulse returned from the exhaust pipe with the floor of the port being shaped to direct this flow precisely where it's most desirable for the custom shape of the combustion chamber.

|

| Quarter View Into The Top Of The Barrel |

When I have achieved precisely what I intend to with this modelling, I shall post some video of the flow modelling during the compression phase of the engine operation but suffice to say for now that this barrel / head combo is going to make more power, more reliably, and allow for a wider range of tuning options whilst offering a complete intake charge burn than anything else on the market available for the air-cooled engines.

Lastly, provision has been made during the design of these heads for a 6mm thick thermal insulating layer between the base of the barrel and the engine cases. This should serve to not only allow the bearings to run cooler and longer, but to keep the air/fuel charge cooler and denser as it enters the combustion chamber for further improved power.

These heads will NOT need to be ported, smoothed or modded in any way to offer outstanding performance. In all actuality, these heads are tuned to the point that any modifications will likely be detrimental to performance.

More info to follow shortly.

Labels:

2 stroke,

39cc,

49cc,

air cooled,

CAG,

Cylinder Head,

Exhaust,

High Performance,

mini moto,

Pipe,

pocket bike,

Port,

Porting,

Racing,

tuning,

water cooled

Monday 24 August 2015

I did some mould making on the CNC yesterday. From this mould is going to be cast a few composite pieces. I'm not allowed to say what they but you'll probably be able to figure it out.

I've got quite a bit of mould cutting to do over the next month or so.. May they all cut so quickly and come out as well :)

I'll be doing complete carbon fibre bodywork for my sons Mini Moto in October..

I've got quite a bit of mould cutting to do over the next month or so.. May they all cut so quickly and come out as well :)

I'll be doing complete carbon fibre bodywork for my sons Mini Moto in October..

Friday 21 August 2015

HITTING THE APEX – UK Trailer

Currently, on my lathe bench

This is what happens to your workshop when you have a motorcycle/mini moto crazy 8-year old in the house.

Mind you, this on top of all the running motors he has already...and yet he started the day by telling me that he has a list of parts he 'needs' to order...

Mind you, this on top of all the running motors he has already...and yet he started the day by telling me that he has a list of parts he 'needs' to order...

|

| The lathe bench this morning. |

I suppose the one redeem in all of this is that he now knows how to build a motor, how to use all the tools properly, and actually insists upon using a torque wrench when he tightens anything..

Labels:

2 stroke,

49cc,

air cooled,

Cylinder Head,

High Performance,

mini moto,

pocket bike,

Racing,

tuning

Location:

London, UK

Tuesday 18 August 2015

Mini Moto / Pocket Bike Exhaust Port Mods and High Performance Pipes

Arguably one of the earlier mods people make to their mini moto / pocketbike, as soon as they're done installing the K&N type air filter is to put on a new pipe.

One hasn't got to look very far online to find a myriad of resellers all flogging pipes of various sizes, shapes and configurations and too, Ebay is loaded with them.

An unfortunate artifact of the vast majority of the pipes you'll encounter for sale is that they're basically stock pipes with a different shaped can or slight variations to the expansion chamber, but very very few will offer any real world difference in performance.

I'm going to focus this post on the Chinese type MiniMotos or 'Cags' for the moment as they're so plentiful, cheap, and have loads of potential if you purchase them with the view towards them being a learning experience and a project versus being a ready-to-run mini moto.

A quick bit of background: As my 8 year old son decided he desperately wanted to race MotoGP one day, the first logical step down that long, winding, and expensive road was the purchase of a mini moto to get him out on the track and get him used to the sensation of a powered 2-wheeled vehicle.

The option was there to simply purchase a Polini or Blata, but I wanted him to understand the bike, understand what happened when he twisted the throttle or squeezed the brake lever. I wanted him to intimately understand the workings of the bike as it would inevitably make him a better racer if he understood the mechanical side of what was going on under his backside.

With the parts being so plentiful and cheap, it seemed a logical step to pick up a 49cc air-cooled CAG and use that as a learning platform towards him being able to do his own work, maintenance and tuning. Quickly catching on, and catching an incurable case of the 'upgrades' bug, he soon started lusting after this component or that and it wasn't long before pipes caught his eye.

Several pipes later and a few semi official, and numerous unofficial dyno sessions later, I'll state that I've personally only found one aftermarket pipe which really delivers any serious performance on a CAG - the Zocchi pipe and can combination. With the usual mods (and a few extra tweaks here and there, this pipe/can combo will give you more mid-range and top end than anything else I've found for a CAG and will do so by an undeniable margin. I'm not referring to little gains or that 'tiny bit extra' .. I'm talking about a major increase in midrange torque and a fantastic top end. Were I to have to put a 'feel' to it, I'd suggest that the Zocchi combination is worth at least another 20-25% potentially beyond any other pipe I've yet seen. --conditionally.

The condition I'm referring to in the above is the gross mismatch between the typical shape of a massaged CAG exhaust port and the inlet for the Zocchi (and most other high-performance pipes). This is not at all unique to the Zocchi, but the rewards in addressing the issue were so richly rewarded by the Zocchi that it's worthy of specific mention.

Here's an image of a typical exhaust port on a CAG 'high performance cylinder' We've just started cleaning the port up, getting rid of casting flaws and doing a bit of reshaping, but you'll note that they're a distinctively rectangular port. This one, after an initial clean up was approximately 25.5 x 18mm.

|

| Near stock exhaust port. |

Now, opened up and cleaned up properly, with a bit of reshaping of the port opening in the cylinder, you can actually get a quite reasonable flow out of these heads and this will make a dramatic improvement in the performance of the motor. Where this falls down quite badly however will be the moment you bolt a typical high-performance pipe to it.

Most aftermarket pipes (in fact, all 9 of the various ones I have here in the shop with me, all have round inlets, and all of them are between 18.5 and 22mm in diameter. The higher performance pipes all seem to be around 21ish so lets use that as a baseline.

I've mocked up quite carefully in cad, the exhaust port profile (as an average of the 4 cylinders I have here (none of them varied by more than 1mm in any dimension) and also the inlet profile for the Zocchi pipe (note, the effect I'm about to show is actually worse with every other pipe I have here).

If you simply bolt a high performance aftermarket pipe to a CAG head using an off the shelf gasket, even if the gasket has been portmatched to the exhaust port on the head, you have what's illustrated below:

|

| Exhaust Port / Header Inlet Mismatch |

I've shown the surfaces I'm referring to in particular in red. This is the view looking down your exhaust port 'seeing' what the exhaust would encounter as it exits the head. The two read areas are not only closing off >20% of the effective port area, the turbulent air created by the exhaust flow encountering these obstructive walls effectively shrinks further, the cross section of the clean flow out of the port. This has a very negative effect on scavenging and on the entire function of the 2-stroke motor as a mechanism. There's such a delicate balance in these motors, as crude as they are in some ways, which allows for exhaust to exit, a fresh air/fuel charge to be brought into the cylinder, any extra air /fuel which escaped into the header is pushed back, then the compression and ignition, only to start the process all over again.

This small animated gif below is the best illustration I've ever seen of how things work in a 2-stroke engine:

|

| The working of a 2-stroke engine. |

You can see clearly how critical it is to be able to evacuate the cylinder of the exhaust gasses and yet do so in such a way as to draw in the fresh air/fuel charge - but without letting it all escape into the exhaust.

*note: this is not my image, I found it. All credit to the original artist whom, if he will make him/herself known, I shall credit accordingly*

Of note, you can see from the animation that it's also important that the flow can travel backwards, into the cylinder in an unobstructed manner, so as to allow escaped air/fuel charge to be used. That return pressure wave effect which forces the unburned air/fuel charge back into the cylinder is the entire point of the expansion chamber on your pipe and it's dimensions are actually the result of a set of dedicated calculations based on a number of engine parameters.

Below is another CAD snapshot, this time showing what the return path would look like for the air/fuel charge being returned to the cylinder from the exhaust system - again, problem areas are in red.

|

| Header / Exhaust Port Mismatch |

Again, the problem areas reduce the effective area by approximately 20% initially, but the effects of the turbulent flow over them has a greater impact.

For lack of a better way of demonstrating this, I did a bit of somewhat crude modelling in my Flow software, and showed an approximation of the behaviour of the exhaust flow from one side, and the unburned air/fuel charge from the other as they would flow across these two mismatches. I thought about trying to save them directly to video but in the interest of portability, I've simply used animated gifs made from captures of the Flow software.

Here you see the two flow models, one going in each direction. If you look carefully, you'll see that clean, unobstructed flow is only happening towards the centre 40% of the openings, whilst around the edges a boundary of turbulent 'air' is causing constriction beyond that of the obstructive walls which the flows are encountering.

|

| Exhaust Flow From Head Towards Pipe |

|

| Air/Fuel Charge Flow From Pipe Back Into Head |

Though these simulations aren't perfect, they're sufficient for the viewer to see the effect of the turbulence at the obstructive edges and their effects on flow. In particular, it's easy to see the flow being concentrated towards the centre of the opening with very little flow occurring at all in the outermost 25%. This has a similar effect to fitting an exhaust restrictor by reducing the effective diameter through which the flow is able to pass at proper velocity.

When time allows, I'll whip up some more elaborate simulations, complete with numbers and pre/post transition flow in both directions. I do think though that the turbulence and its' effects are quite easy to see here.

Without some modification, there's not a whole lot which can be done about this. No amount of massaging on the head is going to do much to rid you of the square port/round pipe problem, Alternatively after sinking good money into a proper pipe, the last thing you'll want to do is take a torch to it.

Initially, I'd looked at what could be done easily by the average home user and explored the options for using compounds such as liquid metal, JB Weld and others which offer a (mostly) room temperature cure whilst yielding a machinable metal-like result.

Something these compounds will not do, however, is take the heat of being in the exhaust port for very long. They might briefly, but they'll soon dislodge and end up in your pipe or perhaps fragmenting and bits being sucked back into your engine with all the to-be-expected, catastrophic results.

The ideal solution might be to have the corners of the port built up with aluminium welding and then reshape the port from scratch, and indeed, this would likely give ultimately the best result under ideal conditions. The two local welding shops I spoke to both wanted roughly £100 per head to perform the welding which seemed very high. I'm sure the work could be had cheaper, but even were it so, you'd still be stuck with completely reshaping the port from scratch.

Looking further towards a solutions which might be more bolt on, I designed in CAD a 'transition' piece which has smooth contoured flow between the two shapes of the port and pipe. Though a longer transition might be gentler, it would also affect the carefully calibrated pipe on which you've just spent so much money (and yes, 10 mm here and there DO matter) so with this in mind, I've made the piece 6mm long and quite carefully shaped the transition to minimise the flow disruption. This isn't a simple 'loft' between the two shapes, though it started that way. A bit of tuning and tweaking to the transition yielded some worthwhile results.

I'd personally suggest removing 2.5-3mm of metal from the face of the port. That will still leave plenty of meat for the bolts to anchor in to, but will serve to alleviate the effects of the nearly 10mm total (assuming 2mm thick exhaust gaskets on each side) of the transition piece. I don't recommend taking any material off the pipe

The transition piece looks much like the image below. This one is one version back from the current one which has now been flow tested, real world tested and is quite close to being a completely finished, tested product. At this point, I can confidently say that there's a consistent gain of at LEAST 17% over the standard configuration and with a couple of pipes, the difference is over 20%

|

| Exhaust Flow Transition Piece V3 |

When fitted, these adapters greatly smooth and improve the flow between the two cross sections, whilst taking up a minimum of depth.

I'm in the process now of exploring casting options as cast in quantity, these could be very economical indeed whilst offering the performance gains which I'm seeing from the prototypes.

They'll come with a pair of exhaust gaskets, one matching the openings on each side and with their use, I recommend using longer bolts with washers and stiff springs to attach the pipe to the head. This configuration has yielded the best results so far in testing and once I changed to this method of attachment, the issues with short gasket life were instantly eliminated. At this point, I attribute the gasket issues to expansion and contraction of the transition piece between the head and pipe and as such, spring loading the joint served to resolve the issue immediately. I may look towards creating a bit of a package with the transition piece, the two appropriate gaskets, and the necessary bolts or studs, washers, springs..etc for attachment if there's sufficient demand. So far, I've 11 pre-orders which took me somewhat by surprise. I'm going to make these kits available soon to anyone who's interested.

Here are two more animations of simulation results, this time with the transition piece in place. The difference in the behaviour of the flows towards the outside 30% of each cross section is immediately apparent and is making a real difference in the overall flow volume.

I'm quite happy with these results, especially from a piece which will be small, easy to install, and straightforward to manufacture. Though a slight massaging for exact port matching will benefit some applications, the vast majority of potential users will be able to bolt these in place, as is, and see immediate, significant improvement in performance.

Here are two more animations of simulation results, this time with the transition piece in place. The difference in the behaviour of the flows towards the outside 30% of each cross section is immediately apparent and is making a real difference in the overall flow volume.

|

| Improved Flow From Port To Pipe Using Transition Piece |

|

| Improved Flow From Pipe Back To Port Using Transition Piece |

As a closing note, just to reaffirm what I've put forward in my CAD images, below are two images, one of a standard CAG exhaust gasket sitting against a largely stock port, and a 2nd of this gasket sitting on the flange of a high-performance pipe - it really is a very undesirable mismatch.

|

| Exhaust Gasket On A Stock Head |

|

| Exhaust Gasket On A High Performance Pipe |

Labels:

CAG,

Can,

Cylinder Head,

Exhaust,

High Performance,

mini moto,

Pipe,

pocket bike,

Port,

Porting,

Racing,

tuning

Subscribe to:

Posts (Atom)